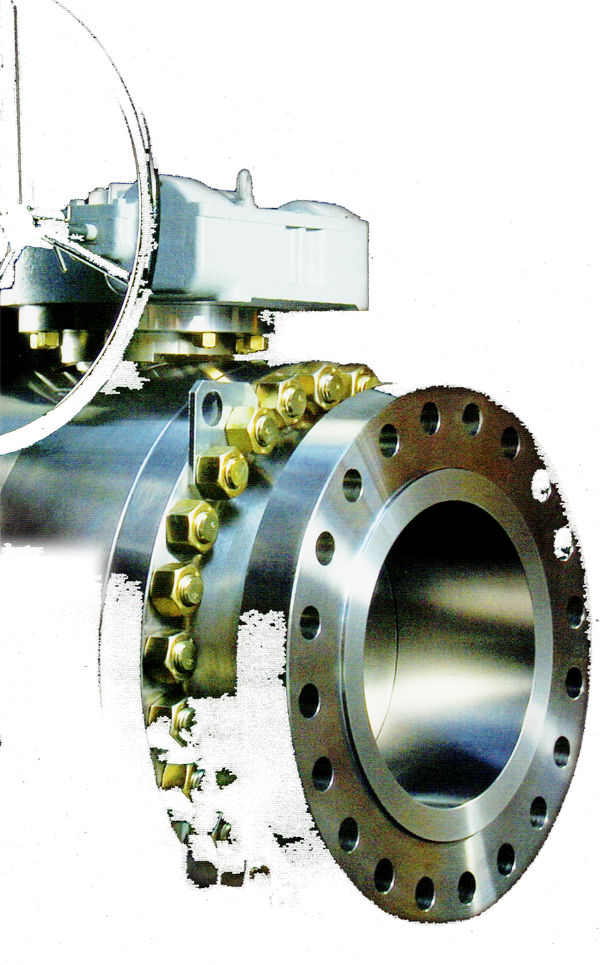

API 6D VALVES

API 6D

Ball Valves

PRODUCT PREVIEW

Basic Design: API 6D (2” – 24”); 26” & up ANSI/ASME B16.47

Inspection and Testing: API 6D Face-to-Face: Flanged ANSI/ASME B16.10;

Flange End Dimensions: 1” – 24” ANSI/ASME B16.5 Buttweld ANSI/ASME B16.25

Fire Safe: API 607/API 6FA

MATERIAL SPECIFICATION

From barstock in carbon steel or stainless steel (304, 316, 304L, 316L, 321) Hastalloy B & C & Alloy 20. Castings in carbon steel to ASTM A216 Gr. WCB. Castings in S.S. ASTM A 351 Gr. CF8/CF8M/CF 8C/CF 3/CF 3M. Alloy20, Hastalloy B & C. Castings in Alloy Steel to ASTM A 217 C5, WC6, WC9, WC12

ONE PIECE /TWO PIECE DESIGN

LACIER One-piece ball valves are high functioning valves, which come with a one-piece inherently flanged body, in sizes of up to 40mm reduced bore and full bore. This design offers the sole benefit of abolishing the opportunity of external leakage to the atmosphere through bolted body joints. These eco-friendly and great reliability valves are preferred in critical applications where the media is expensive, volatile or toxic, and where external leakage or depletion is intolerable. The two-piece design supplements the one-piece design in sizes of 50mm and above reduced bore and full bore.

THREE PIECE DESIGN

Ball Valves of three piece design are the most simply maintainable online. By removing the a few body bolts and loosening a few more, the body can be swayed away using the loose bolts as the pivot, to carry out any installation or upkeep process on the valve. This feature reduces upkeep interruption to the least.

LACIER ball valves can also be used in special operational situations with complex service, strong corrosion and sour service. In order to meet such working service conditions, LACIER employs Inconel, Monel as body material. All internal parts contacting the fluid service are also made of Inconel, Monel or other alloys. In addition, valve trim can also be provided with NACE treatment.

OPTIONAL SEAT SELECTION

Peek offers a unique combination of chemical, mechanical, and thermal properties. This material is exceptional for high temperatures up to +260C

Metal seats hardfaced with Stellite 6 are recommended for use in high temperature fluid and gas applications. The temperature range of the material allows it to get up to the maximum temperature of the valve body material.

RPTFE’s mechanical assets are improved by adding a part of filler material to deliver improved strength, consistency, and wear endurance. The temperature range of this material is -46C to +232C (-50F to +450F).

Teflon (Virgin PTFE) is a fluorocarbon-based polymer. This material has exceptional chemical endurance and co-efficient of friction. The material is not recommended for liquid alkalis and flourine. Its temperature range is good from -34C to +204C (-30F to +400F).

MAJOR FEATURES

The modest design of the ball valve makes it stress-free to repair in the field. LACIER Ball Valves are designed to meet API 6D specifications, and API 6FA and 607 fire safe requirements. Internal parts are easy to coat, making an enormously large range of trims available. Upstream sealing permits the valve seat seals to be tested by bleeding the body cavity with the valve either open or closed. Includes a seat injection system to provide a fast simple way of reinstating tight shutoff if any external entity should damage the seating surface. This system can also be used for routine flushing of the seat ring area in services where this may be required. Provided with stem sealant injection system to provide a secondary seal around the top stem.

FIRE SAFE CONSTRUCTION WITH SECONDARY METAL SEAT

LACIER’s ball valves have been put through fire tests and if need be supplied according to API 6FA and API 607. Regardless of their materials, the soft seat insets, will probably fail when exposed to unexpected high temperature surroundings. LACIER provides a fire-safe design, which may significantly block leakages through seals when affected by high temperatures. If the seat insets are damaged or scorched, a metal to metal seal is created between the lower diameter of the seat and ball, while the seat to body seals, the stem packing and the end connections to body seals are designed to oppose high temperature and continue to be unaffected.

ANTI-STATIC DEVICE

To allow static charges to go to the piping, springs are offered at the stem. This eradicates the electrostatic charging of the ball.

TRUNNION MOUNTING

Operating torque remains low, even at a full measured working pressure, this occurs from the fact that the additional resistance between the ball and seats is prevented by the trunnion mounted stem which absorbs the impact from the line pressure.

SELF-LUBRICATION

For stem bearings, stem seals, and body seats low resistance PTFE is used. Similarly for seat inserts low resistance materials such as Nylon are used. To achieve a more certain operating torque for the life of a valve, self-lubricating seals and steam bearings are provided.

DOUBLE BLOCK AND BLEED

The seats are of both-side-sealing type that goes to say that they tighten both on the upstream or downstream flank and inside the ball valve. Whether in the open or closed position, pressure on each side of the ball is obstructed from the body cavity by the seat rings contrived to self relieve therefore no pressure build up can arise in to the body cavity. This can then be vented to the environment or emptied through the body port.

BI-DIRECTIONAL SEAT RINGS

To be able to shutoff the fluid apart from its pressure dispersal, each seat ring has been engineered to be of a self-regulating floating type design. The downstream seat ring warrants a tight shutoff while the upstream seat ring fails, thus contributing to a double barrier against the fluid. A relief valve is incorporated to the vent connection to control the fluid, since the excess pressure of the fluid, if it is liquid, cannot be released back into the pipeline.

VALVES BORE

The design of the bore of the valves is either of full or reduced type with the minimum bore size conforming to the requirements of API 6D.

BALL SEATING

Valves with rating inferior than ANSI Class 1500# have a seat inset prepared of elastomer to permit double ball sealing, a primary metal-to-metal and a secondary soft type seat. Valves with superior rating are offered with a seat inset made of thermoplastic resin (like Nylon or RPTFE) to ensure a soft bubble-tight seal only against the ball. In addition, a double plastic + elastomer seal is recommended for valves having a stainless steel trim with no plating to be used in case of extremely low pressure services.

SEALEANT FITTING

Sealant lubrication fixtures come customary with LACIER’s design. In the occurrence of the seat inset or stem seal impairment, external or internal seepage can arise. Emergency sealant injection can uphold the reliability of the valve by integrating a sealant seal around the stem or between the seat and the ball until the time that the valve may be appropriately examined.

BODY VENT AND DRAIN

In both open and closed situation, the body cavity may be drained.

STEM SEAL WITH BLOW-OUT PROOF STEM

The stem is liberated of the ball and therefore is of a blow out proof design. As a fundamental part, the stem has a flange at its lower side. The stem flange averts the stem from blowing out. This feature also permits substitution of stem packing while the valve is under pressure. A generously balanced mating joint transfers the torque to the ball, hence the stem is not disturbed by the side impacts. The stem being separable from the ball is thus blow proofed thanks to an important support lying against the bonnet through a self-lubricating thrust washer.